Automotive products

At Mitsubishi Logistics, we respond to the various automobile-related logistics needs of our customers.

Many finished car and part manufacturers use our services, and we are always expanding our selection and range of services to meet customer needs.

Examples seen through video

One-stop service

We have developed domestic Japanese logistics, as well as a logistics service abroad and for international maritime and air transport. We offer one-stop logistics services from overseas locations to Japanese factories and from designated locations within Japan to overseas locations through our Japanese domestic and global logistics networks.

Export packaging

We handle a wide variety of products from finished car and part manufacturers.

From heavy cargo using hoist cranes to lightweight cargo with many SKUs, we safely package our customer's valuable products and deliver them to their destination.

We plan and propose packaging specs fit for transport to the destination based on product characteristics, and we propose the optimal packaging plan in terms of safety and costs.

We are actively working to optimize and standardize our warehouse operations by digitalizing packaging specification sheets, introducing our own unique cargo loading plans, and more. We manage the work progress of each assembly line while also working for uniform work quality by utilizing tablet computers and standardizing packaging work.

Import part storage

From the recent trend of seamless part commonality on a global scale, the production of automobile parts that were previously procured domestically has shifted overseas, and increasing number of schemes exist to import these parts to Japan.

We own warehouses near six major ports in Japan (Tokyo, Yokohama, Nagoya, Osaka, Kobe, and Fukuoka), and can help with unloading, storage, packaging conversion, shipment, and delivery to factories within Japan. We utilize our in-house developed Warehouse Management System (WMS) in our warehouses, and we work for optimal inventory control, improvements in storage efficiency with KPI management methods, and improvements in productivity for in-warehouse work.

Packaging conversion

We contribute to the optimization of the entire process from procurement to manufacturing by converting packaging from the type used during transport for efficiency to the type suited for efficiency at the destination factory.

We engage in precise operations by carrying out handy inspections during each process. We also arrange and manage materials, such as plastic containers, based on the customer's production plan or warehouse delivery plan.

Parts center operation

We operate an imported parts center for finished car manufacturers.

We offer consistent support from import customs of the many tens of thousands of types of spare parts to inventory management, picking, shipment packaging, and small cargo delivery to destinations across Japan (distributors, etc.). We also offer supplementary services including a call center and simple inspections of part quality.

Assembly

We assemble parts, process parts, and more, based on finished car manufacturer quality standards. By assembling or processing parts in the warehouse before entering the production line, it becomes possible to introduce the parts to the assembly line right away and this contributes towards a reduction and optimization of work within the warehouse.

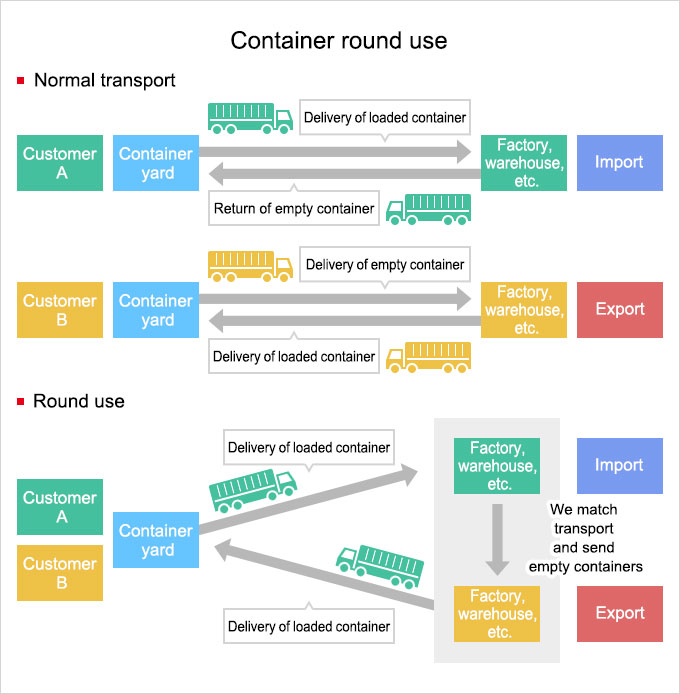

Container round use

We are working to reduce transport distance and costs by matching import and export container transport.

Container round use responds to the recent lack of drivers and easing of traffic and is gaining attention from the perspective of reducing CO2 emissions.

JIT (Just In Time) delivery

We minimize factory inventory and support customer productivity improvements at warehouses with sequential delivery and JIT (Just In Time) delivery, where the necessary item is delivered in the necessary amount at the necessary time to match production plans.

At Mitsubishi Logistics, we create delivery systems that match our customer's designated time-based systems. We also are working to reduce our impact on the environment by using returnable (reusable) containers when shipping.

Other services

In addition to the above services, we can respond to the following requests.

- Parking lot operations

- In-factory logistics

- Operations of dangerous goods warehouses

- Management of tax ID database for imported parts and inspection of status of optimal tax rate

- Optimization of logistics corresponding to CASE (Connected, Autonomous, Shared, Electric)

- Response to digital transformation and work automation

- Utilization of unused factory land