Demonstration Experiment of Real-Time Traceability in Airfreight to NY -Using “SmartBarcode®” from LOZI Inc.-

Sep. 14, 2020

Mitsubishi Logistics Corporation (hereinafter “Mitsubishi Logistics”) performed a demonstration experiment on real-time traceability in the air transport of fresh fish for New York in cooperation with LOZI Inc. (headquartered in Nagoya City, Aichi; hereinafter “LOZI”)

- 1Background

Mitsubishi Logistics provides airfreight services in collaboration with associated companies and agencies all over the world. We handle many perishable foods, pharmaceuticals, and healthcare-related goods, and so we are working on the creation of a system which can provide the shipping status in real-time (real-time traceability) for the purpose of improving transportation quality.

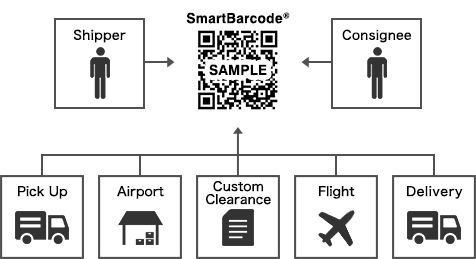

While we push forward with this plan, we took note of the LOZI SmartBarcode®, which is an easy-to-use way to share and manage large volumes of data with a single QR code, and performed a demonstration experiment with it.

[About SmartBarcode®]

Facilitates information reading and input in smartphones using a variable identification code that can be entered developed by LOZI based on the QR code. - 2Experiment Overview

With the cooperation of our customer, we performed the experiment when shipping of fresh fish from Toyosu Fish Market in Tokyo to a Japanese restaurant in New York in late July.

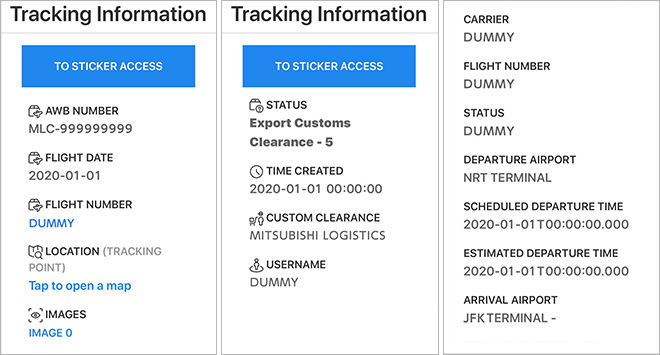

We attached a SmartBarcode® to the shipping box with the fresh fish and our staff in charge at scheduled tracking points (about 10) read the SmartBarcode® on the shipping box using their smartphones. With this process, the shipping status information was successfully stored in a database. Checking these information and data, we verified the validity of the pre-designed information processing flow and system operations.[Reference]

- The main tracking points were as follows.

Toyosu Fish Market (Pick Up), Narita International Airport (terminal arrival), export customs clearance, import customs clearance at JFK International Airport in New York, transportation to the destination, delivery - Import and export permits are entered by the customs broker’s staff using the SmartBarcode® attached to the invoice.

- During the flight, the flight schedule was automatically retrieved and displayed in the traceability system.

- In connection with the terminal arrival at Narita International Airport and the departure for local delivery in New York, a picture of the freight case was taken with a smartphone and the image was uploaded to the system.

- The main tracking points were as follows.

- 3Future Developments

During the experiment, three parties—our customer, the consignee, and us—tracked and shared the shipping status in real-time, and the customer gave high marks to the results of the experiment. For future practical use, we will examine the data obtained from the experiments and the issues to be addressed. At the same time, we are working on improving usability and adding the function of managing positional information during transportation. Moreover, we will examine application in air transport of products such as pharmaceuticals, specialty chemicals, and precision machines, for which traceability is vital, as well as in the shipment of perishable foods.

Mitsubishi Logistics is working on “end-to-end visibility” in international logistics by actively utilizing new technologies.

[About LOZI Inc.]

| Business overview | Developing and providing logistics solutions using SmartBarcode® and robots |

|---|---|

| Established | November 2018 |

| Address | 1104 Nagoya Konoike Bld., 2-19-1 Nishiki, Naka-ku, Nagoya-shi, Aichi |

| Representative | Martin Roberts (Shigeo Watanabe) |

| URL |

Click here for the Japanese version of this news.